The Decline of Machine Building

The 1950s was a busy decade for the British knitting machine building industry as companies replaced old worn out machines and invested in new machines.

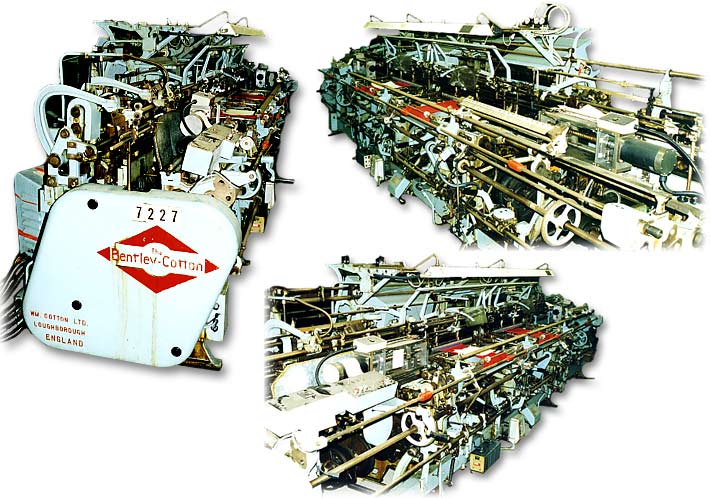

One of the last Bentley machines to be made

The Bentley Engineering Co. Ltd emerged during this period as the largest knitting machine company in the world with a staff of 4,000. Takeovers gave the company control of Wildt & Co. Ltd, William Cotton Ltd, G. Blackburn & Sons Ltd, William Hammond & Son Ltd, J.T. & C. Grudgings Ltd, G. Woodcock & Sons Ltd, T. Grieve & Co. and Clarendon Eng. Co. Ltd. The company continued to expand and had 9,000 staff by 1970. Rival firm G. Stibbe & Co. Ltd also expanded to own S. A. Monk Ltd, and I. L. Berridge Ltd; it employed 2,550 staff in 1969.

New competition

Overseas competition for the British machine companies increased with the expansion of the Italian machine building industry. Giorgio Billi introduced his 4-feed circular hosiery machine in 1961. By knitting more than one yarn at a time, the machine cut the time taken to produce garments and led the way for further developments. Between 1955 and 1973 the number of yarn feeders increased from two to twelve. By the end of the 1980s, the speed of the machines rose from 260 revolutions per minute to 1,200. The machines were able to complete more tasks automatically and fewer people were required to run them. In the 1960s labour costs made up half of the production costs for a pair of stockings. With the improved technology, labour costs fell to 15-20% of production costs.

Far Eastern countries developed important machine building industries in the 1970s and 1980s. Shima Seiki of Japan gained a reputation for innovative flat bed machines. Taiwan and South Korea followed with a focus on the production of large diameter circular machines. The rise of overseas machine building industries is illustrated in trade journals of the 1970s. Advertisements were no longer dominated by British companies, instead nearly 90% of all companies advertising were from overseas.

Demanding times

For many British knitting machine companies declining sales were linked to a failure to develop the technology in demand. The Bentley group acquired a significant range of expertise through its takeovers, but this did not stop it losing its share of the market. The decline of fully-fashioned stockings meant that the machines of its William Cotton division were no longer in such demand. The company responded to the move to circular machines through the introduction of twin feed machines. These machines, however, could not compete with the faster multi-feed machines developed in Italy. This problem was also faced by other overseas companies and many in the USA and Europe were forced out of business. After the collapse of the double jersey market in the mid-1970s, the Bentley group slipped into decline. In 1982, Bentley's owner, the Sears Group, stated that they were no longer willing to subsidise the company and the surviving divisions of the business were bought out by four former directors.

Stibbes, the only other major British manufacturer also went into decline in the 1970s. The loss of the circular machine market to Italian companies left the company struggling and it also suffered from being over-committed to double jersey. After the company was declared bankrupt in 1975, the S A Monk division was relaunched as a separate company. The owner of Monks, George Ferguson, subsequently acquired the remains of Bentleys after the management buyout failed in 1983.