Advances in Knitting Technology

The 1970s saw the introduction of early computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. Designers used the CAD system to create product designs and transferred them to CAM machines to manufacture the final product.

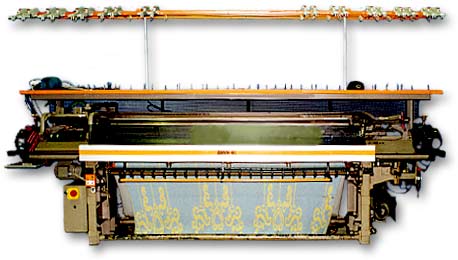

Selectanit V Bed Computer controlled knitting machine.

CAD/CAM technology replaced the mechanical shaping and patterning devices on machines with electronic controls. The systems enabled companies to respond quickly to changes in demand. New designs could be set up using CAD and instantly produced on the CAM machine.

Early systems were expensive and only the major companies could afford them. In the 1980s and 1990s CAD/CAM fell in price and small and medium sized companies invested in the new technology.

The introduction of computerised technology enabled companies to work globally. Fast communication systems have encouraged production to move away from East Midlands' factories to other countries. Designs produced in the UK can now be instantly transferred electronically across the world to low-cost producers.

Whole Garment knitting

Cutting fabric into shapes and sewing the pieces together has been used to create garments since the eighteenth century. From the 1970s companies researched more efficient technologies that produced a complete garment in one process without the need for sewing. Garments could be knitted quickly and without the loss of fabric associated with cut and sew techniques.

'Wholegarment' technology was further developed in the 1990s by Shima Seiki of Japan. Shima Seiki achieved this advance in knitting technology by developing the slide needle. The slide needle resulted from research into the latch needle and the knitting process. The needle consists of a hook located centrally between a flexible two-piece slider mechanism. Stitches are transferred by the sliders during the knitting process.

Wholegarment clothes provide greater comfort than cut and sew clothes. The absence of seams means that the fabric can fit close to the body and stretch more easily. Wholegarment machines are also capable of producing complex designs. 2D fabric is replaced by 3D knitwear shaped and pleated as required.

Digital printing

Textile printing on garments such as sweatshirts, t-shirts and babywear has been dominated by screen printing technology since the 1970s. Set-up costs for screen printing have, in recent years, conflicted with the trend for short production runs. Advances in digital inkjet printing technology during the 1990s and early 2000s have enabled machines to be built that can cost-effectively produce small print-runs on textiles.

Designs can be transferred directly from a computer and printed onto fabric in almost the same way as a word-processed document is printed onto paper. Colours, sizes, shapes and looks of designs can be changed quickly using computer software. The flexibility of the technology allows samples and short runs to be produced easily without the costs of setting up screens and wasted ink. To prepare fabrics for digital printing, they are treated to ensure that fibres absorb the ink at the correct rate. The printed garments are steamed to fix the dye on the fabric.

It has been estimated that by 2010 10% of all printed textiles will be digitally printed.