Steam Powered Cotton Spinning

In 1712 Thomas Newcomen invented a steam-powered engine. He realised that steam produced by heating water could be trapped in a cylinder and that sufficient pressure could be built up to raise a piston.

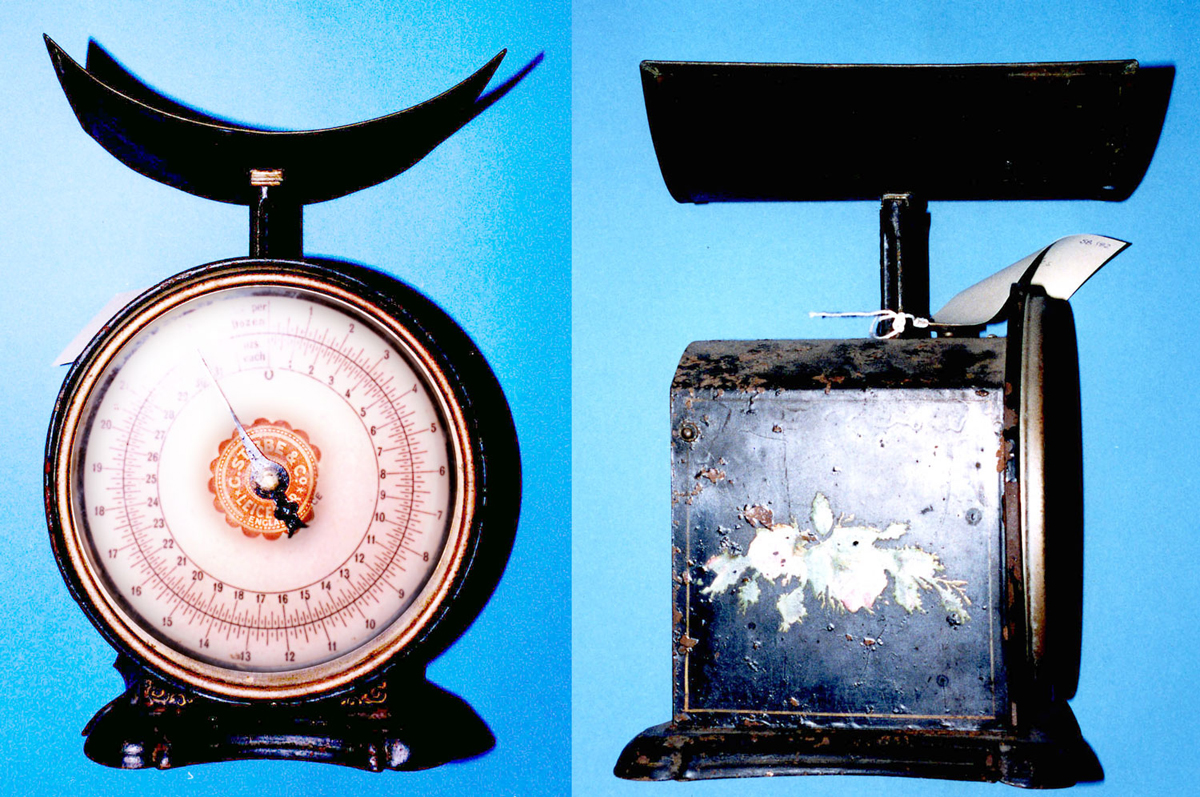

Scales for weighing socks.

When the steam cooled, pressure was reduced, and this caused the piston to fall. The vertical motion of this engine meant that it had limited applications, but with a beam attached to the piston it was successfully used to pump water out of mines.

James Watt's improvements

James Watt realised the potential of Newcomen's invention and began experimenting to see how the vertical motion of the piston and beam could be harnessed to drive other machinery. In 1782 he built a rotary-motion steam engine which used a series of gears to convert vertical movements into rotary motion. Watt marketed his engine in partnership with Matthew Boulton, the Birmingham entrepreneur. To highlight the capacity of the engine, Watt compared its strength with the strength of horses: a twenty horse-power Watt engine provided the same power as a team of twenty horses.

From waterwheel to steam engine

Arkwright's water frame was originally designed as a hand-operated machine, but to control its use, the 1769 patent restricted its use to large mills of at least one thousand spindles. The system of water-powered mills was soon copied and by 1788 there were over 200 of them, many in Derbyshire and Nottinghamshire and a few in Leicestershire. Following the introduction of rotary motion, steam power was first used with Arkwright's frames in 1785 at Papplewick Mill, Nottinghamshire. Steam power was only widely applied at the end of the eighteenth century and was responsible for a quarter of the cotton processed in 1800.

Competition from Lancashire

The East Midlands knitting industry and the Manchester textile industry bought most of the cotton yarn produced by the new mills. Due to technological improvements, mills in the East Midlands were overtaken by mills in Lancashire. Adoption of Cartwright's power loom after 1785 caused a rapid rise in demand for cotton yarn which prompted further growth of mills in the north-west of England. By 1836 competition from the large numbers of mills in the north-west had affected the numbers of mills elsewhere in Britain, though the knitting industry in the East Midlands continued to support eight mills in the Mansfield area and eight in Derbyshire.

With cotton yarn widely available in the East Midlands, cotton was a popular choice for knitting. It rapidly became cheaper than silk and finer than wool. Cotton, with the new technologies to process it, was used for a wide range of cotton hosiery and by 1815 production of cotton hose occupied the largest numbers of frames in the knitting industry.