Fashionable Items P - W

From Plating to Wristlet.

Plating

Plating involves using two yarns at once during the knitting process, having one yarn on the face, and another on the reverse. Alternating the yarns between the front and the back of the fabric can be used to create patterns in garments.

Plating was used to add linings to garments and to add strength or warmth. Often a cheaper yarn was used for linings.

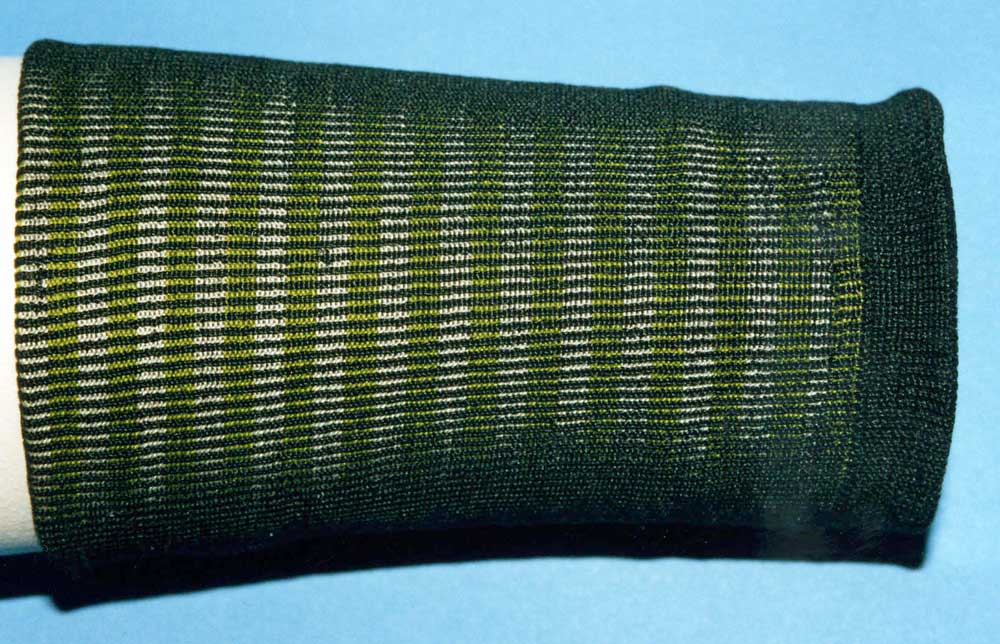

Sock with plated lining

A sample tennis sock in white rayon plated onto cotton for strength. The heel and toe are in plain cotton. The turndown ribbed cuff has green near the edge and two bands of patterning. On the sole is printed 'Morley, Made in England, Artificial Silk & Cotton' and Morley's trade mark of a wheel with wings. The printed card lists the places where Morley had factories. A separate card has samples with different colourways of cuff on it.

Pullover

A garment designed to be pulled over the head. The term is often associated with sweater-like and sleeveless garments extending from neck to waist or hips.

Pullover

A man's pullover designed and knitted on a flat bed machine by Linda Brockway using over twenty shades of wool. The pullover has a crew neck and ribbing at the bottom and at the wrist of the sleeves. The body and the sleeves are knitted with rows of lozenges, each row in a different colour. Linda Brockway called this design 'Kaleidoscope' when she first started making them in October 1984. The pullover has a printed label 'Individually made by Linda Brockway...' and a printed card 'Linda Brockway Knitwear ...Price £40.50, Size Medium, Kaleidoscope, Individually machine knitted in the home of the designer using twenty muted colours of Shetland Wool. An ever-changing selection of colours and different starting points ensures each garment is unique'. Described by the Linda Brockway as "the best-selling design of everything I have done."

Rayon - Artificial Silk

Silkworms have been raised and farmed for thousands of years to obtain silk thread. In 1734 Reaumur, a French naturalist, suggested that as silk was only a dried liquid gum then it should be possible to copy the silkworm process and manufacture silk from gum and resin. In 1883, Joseph Swan from England patented a process for creating threads from a mixture of wood and cotton pulp squeezed through small holes. The following year, Count Chardonnet, a Frenchman, produced artificial silk by the nitro-cellulose process at his factory in Basancon.

Scientists were inspired by Swan to investigate artificial silk fibres. In 1892 Cross and Bevan took out patents for the viscose process. The process involved treating cellulose with caustic soda to create a thick brown viscous solution. In the same year Fremery and Urban from Oberbruch, near Aachen, Germany, added copper sulphate and ammonia to a viscose solution and created the cuprammonium process. The cuprammonium process was further developed by J P Bemberg of Wuppertal-Oberbarmen, Germany in 1901. The company’s yarn made by the process became known as 'Bemberg'. Courtaulds worked to improve the viscose process from 1904. After the First World War, the Dreyfus brothers from Switzerland began manufacturing fibres by the acetate process. In 1927 they took over the British Celanese Company from the Government.

The term 'rayon' first emerged in 1924 to describe synthetic fibres made from cellulose. The fibre could be produced by the viscose, acetate, cuprammonium, nitrocellulose or other processes. Cellulose is sourced from the cells of plant life. Wood and soft fibres from seed heads, particularly cotton seed heads, are main sources of cellulose. Cotton was too valuable for use in rayon, but by-products of the cotton industry were available. The shorter cotton hairs, known as linters, were discarded from the cotton yarn manufacturing process and could be used to make rayon. Linters produced higher quality rayon yarn and wood pulp was used for standard rayon yarns.

Artificial silk enabled manufacturers to produce a continuous thread with a regular form. Other yarns such as wool and cotton required short fibres to be spun together to produce a thread. Rayon manufacturers were also able to control the thickness of the thread and produce yarns suitable for a range of uses. Fine threads could be created to imitate silk and knit fine gauge stockings, or thicker threads provided yarn for more hardwearing clothing. Rayon threads were also twisted to develop yarns with specific characteristics, including appearance and strength. Chemicals, such as titanium oxide, could be used to take the shine out of rayon and give it a matt appearance.

Romper suit

Originally a baby's one piece suit covering the upper body and the upper legs, and incorporating buttons or fasteners to close the crotch. An American term in use from about 1910, and in Britain from around 1918.

Romper suit

Child's lemon yellow romper suit knitted in horizontal fancy rib pattern with plain rib neck, cuffs, waist and leg holes. Opens at front to waist with 3 buttons, and at crotch with 3 buttons. Dark brown knitted drawstring at waist, matching edging. Factory sample, size 14/21, dated 19.7.72.

Sampler

A piece of work produced to show fabric and design examples. Samplers were produced for several reasons. Knitters and cheveners keen to gain employment or perhaps earn more money produced examples of their work for employers to look at. Sometimes they were made to try out a new stitch or different combinations of colours. Salesmen used samplers to provide customers with examples of the types of work that could be produced by their firm.

Sampler

Black silk rectangle with lozenge patterns in lace stitch, received with the information "Made on German lace machine 1908" from Allen, Solly & Co Ltd.

Scarf

A piece of fabric produced in various widths and lengths, worn around the neck, across the shoulders or over the head for warmth and decoration.

Scarf

Machine knitted in cerise and reseda green acrylic these gloves and scarf have a simple pattern of triangles. They were a Christmas present in 1985, and typical of the colours of mid 1980s, but have never been worn. The scarf and one glove have labels 'Made in Taiwan'. The set comes in a polythene bag labelled 'Match Makers'.

Silk

Silk fibres were first used 4,000 years ago when the Chinese began farming silkworms. Silk did not reach Europe until the fourth century B.C. and it was not farmed until 550 A.D. when two Persian monks brought silkworms to Constantinople. During the following five hundred years, the rearing of silkworms, 'Sericulture', spread to Spain and Italy.

The silk fibres used to produce yarn are obtained from the silkworm when it spins a cocoon before turning into a silk-moth. When spinning the cocoon, the silkworm produces a fluid from a gland, which hardens instantly when brought into contact with the air. Initially an outer case is spun creating what is known as 'floss' silk. When fully encased, the silkworm continues to fill the case, spinning a silk filament in a figure of eight motion. The process takes three or four days and can produce between 1000 and 3000 metres of single continuous filament. If left to mature, the pupa develops and emerges as a silk-moth after fourteen to twenty days. Before emerging from its silk case, a brown liquid is produced by the moth to weaken the cocoon and reduce the effort required to break through. When farming silkworms, so as to prevent the moth damaging the silk filament, it is dropped into boiling water.

The silk fibre extraction process begins by removing the outer floss silk from the cocoon. After removal of this waste material the end of the inner cocoon filament is put onto a reel and the cocoon is unwound. To give strength to the thread, an average of five filaments are wound together to form a thread. This creates what is known as 'hosiery one thread'. A hosiery one thread equates to approximately thirteen to fifteen deniers. The properties of the thread include strength equivalent to that of steel (when considering the strength to weight ratio), flexibility, elasticity, and an ability to absorb up to 30% of its own weight in moisture whilst not feeling moist to touch.

The desired strength or look of a silk yarn is achieved by winding two or more threads together. Changing the number of threads used and how they are twisted together can produce a range of styles, for example tram silk, high-twist silk, organzine silk, grenadine, crêpes, compenzine, and poil. The twisting process is also used for rayon and nylon yarns.

Silk yarns

Compenzine

The compenzine style thread is also known as compensene or compensated silk. Compenzine shares similarities with grenadine in its processing. Two threads are independently highly twisted about sixteen times per centimetre in the same direction. The two twisted threads are then combined with an untwisted thread and twisted approximately sixteen times per centimetre in the opposite direction to that of the twisted threads. The process creates tight, smooth, hard thread. The yarn gives a similar appearance to the crêpe yarn and is sometimes wrongly referred to as crêpe.

Crêpe

The crêpe silk yarn involves two stages of thread combination. At the first stage, two untwisted threads are combined by twisting them in one direction at the rate of approximately twenty turns per centimetre. Also at stage one, two further threads are combined by twist, but this time in the opposite direction and at about eighteen turns per centimetre. The two resulting combined threads are then in turn combined in the same direction as the yarn with the lesser turns per centimetre. The threads are combined with about two turns per centimetre. In common with other highly twisted styles, the yarn produces a dull, elastic and strong fabric. The snag resistance characteristic creates a more durable stocking.

Grenadine

Grenadine style yarn is a high twist form of the organzine style yarn. The single silk threads are twisted around fourteen turns per centimetre in one direction and then the twisted threads are combined and twisted together with about thirteen turns per centimetre in the opposite direction. The yarn retains the elastic character of organzine, and at the same time benefits from the additional strength created by the increase number of twists per centimetre. It has a non-shiny or matt appearance.

High Twist Silk

The high twist silk style is created in the same manner as tram silk. Two or more threads of silk are twisted together, but instead of the two turns per centimetre used with tram silk yarn, between four and eight turns are made per centimetre. This results in a thinner and harder yarn. Once knitted the yarn gives a better feel and its wearing quality is improved. The finish of the fabric also has a duller appearance.

Organzine Silk

The organzine silk style yarn builds upon the tram silk and high-twist style yarns. Individual threads of silk are twisted in one direction about six times per centimetre before the threads are combined and twisted together in the opposite about five times per centimetre. The result of this twisting process is a yarn with improved elasticity and strength.

Poil

The poil style silk yarn is easily created by twisting a single thread of silk up to thirty times per centimetre. The twist is often a left-hand twist.

Tram Silk

The tram silk yarn is created by twisting two or more threads of silk together. The twist is at about the rate of two turns per centimetre. Up to the middle of the twentieth century, tram silk yarn was principal style of yarn used for knitting silk stockings. The finished stocking had a 'fuzzy' appearance and snagged easily. In response to changing demands for hosiery with a more matt appearance, new styles were created by altering the number of threads used and changing how they were twisted.

Silk stocking

A woman's fine pink silk stocking made on a 52 gauge stocking frame. The heel, toe and English foot are of thicker silk. Marked below welt with 'M' for I & R Morley. It has a handwritten label 'Fine Silk Hose by I & R Morley'. The stains are from tar used to seal the bottle which contained it and a quantity of lace when they were buried under the foundation stone of the Wesleyan Chapel, Mansfield Road, Nottingham. They were recovered when the building was demolished in 1977.

Socks

The term sock generally refers to hosiery that covers the foot and extends to somewhere below the knee. The introduction of full-length trousers in the early nineteenth century meant that long stockings were no longer required to cover the leg. Shorter stockings or 'half hose' were introduced to cover the lower leg and a ribbed edge was added to help support the sock on the leg.

Socks soon began to replace the stocking in men's fashions. Cotton and wool were widely used to knit socks, while silk was used for high quality socks. The second half of the nineteenth century saw a range of sock designs become fashionable. Socks with coloured bands, black socks, and brightly coloured socks went through phases of popularity.

By the 1930s, Morley's had introduced sportswear socks for women. Men's socks developed using new fabrics including rayon and lisle, and patterned designs were introduced. 'Shot-effect' socks incorporated two contrasting colours, one colour on the outside and the other on the inside. The inside colour was revealed when the sock stretched. Socks with rubber threads (Lastex) in their ribbed tops were introduced in the 1930s with claims of their self-supporting properties.

During the Second World War people had to be careful with resources. Many old knitted clothes were unwound and the yarn reused to knit new clothes. Magazines and newspapers printed knitting patterns for socks and people turned to domestic circular knitting machines for sock making. Recovery after the war brought new manmade fibres to the market and socks were produced with nylon, Terylene (Polyester) and acrylic yarns. The post-war era saw the return of colour to socks. Patterned designs and vibrant colours were in fashion again. In the 1970s and 1980s the sports look became popular and sports socks in terry-knit (plush) were widely worn.

In the modern high street a huge range of socks are sold in many shapes, patterns and colours. Technology continues to play a role in the latest developments. Socks are now available with antibacterial properties to keep feet feeling (and smelling) fresh.

Byford Stretch Sock

Pair of men's ribbed socks, red nylon with wavy black and white pattern. Stamped 'The Byford S-T-R-E-T-C-H Sock'.

Stockings

Since the introduction of tights in the late 1960s, stockings have declined in popularity, but it was the stocking that inspired William Lee to invent the knitting frame. Stockings are tubes of fabric that cover the foot and extend to the knee or above. Unlike tights, stocking legs are not joined at the body and are often worn with garters or suspenders to hold them up.

From the sixteenth century to the early nineteenth century men commonly wore stockings. Prior to the introduction of trousers, garments such as breeches did not fully cover the leg and stockings were used to hide the flesh. Elaborately decorated silk stockings were worn by the wealthiest in society. Trousers were widely worn from the early nineteenth century and socks were worn instead of stockings.

For women, long dresses were in fashion until the early twentieth century and the leg was rarely seen. Beneath the dress simple stockings were often worn in case the leg should be seen. Although they were hidden, quite elaborate stockings were occasionally worn. Periodically (1750s, 1770s, 1820-40) shorter skirts entered into fashion that allowed decorative stockings to be worn and be seen. The Victorians used developments in technology to produce stockings in an array of new colours. Chemical dyes created much brighter colours than those obtainable from natural dyes.

In the twentieth century new manmade fibres replaced natural fibres (wool, silk and cotton). Rayon and later nylon revolutionised stocking production and provided women with cheaper stockings. Flesh tones became popular during the 1920s and have remained so up to the present day.

The introduction of tights in the 1960s provided women with a more convenient form leg covering. The body piece of a pair of tights helps to hold up the legs and suspenders are not required. Stockings declined in importance as sales of tights increased.

Tights

Knitted tights were worn by men from the late eighteenth century and by actresses from the 1880s. They became a fashion garment for women in the 1960s when very short skirts were being worn.

During the 1960s manufacturers experimented with designs that combined two stocking legs into one garment. One idea simply sewed a stocking to each leg opening on a pair of pants to create a pair of tights. Another prototype involved knitting a long tube of hose the length of two legs, and cutting an opening midway along the tube to provide access. The body section was restricted to the width of the tube and did not provide much support. Eventually a satisfactory method of manufacture was identified that cut a slit into two legs and then sewed them together. Tights rapidly gained in popularity and soon outsold stockings.

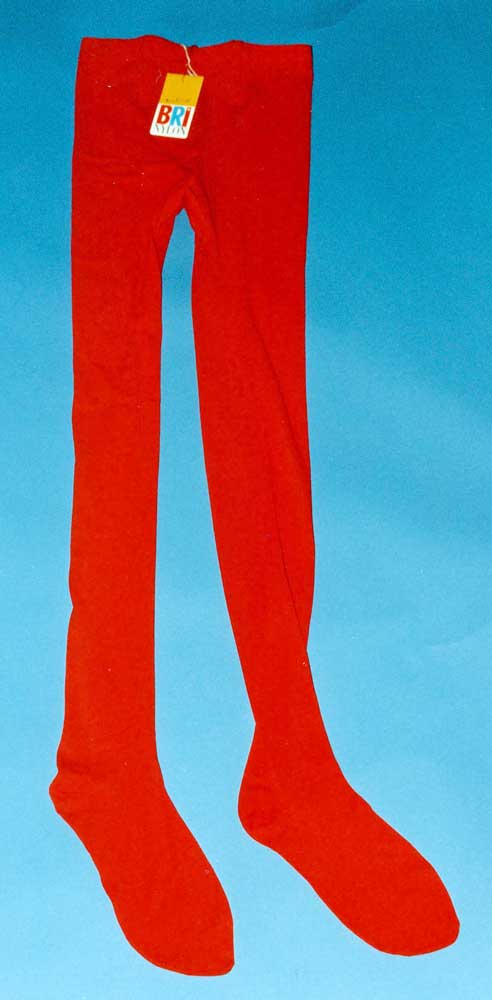

Tights

Pair of women's 'Emblem' brand tights in opaque red Bri-nylon with ribbed body and elasticated waistband. Size small, in original box.

Undersleeves

Undersleeves are separate sleeves worn under the sleeves of a main garment and visible through the garment or extending beyond it.

In Tudor times undersleeves were often worn underneath gowns and made of the same material as the underskirt or kirtle. By the mid nineteenth century, three quarter length sleeves were often complemented by undersleeves, made of muslin, net or lawn and decorated with whitework embroidery or lace. The early twentieth century saw a revival of the undersleeve worn with short upper sleeves finishing at the elbow.

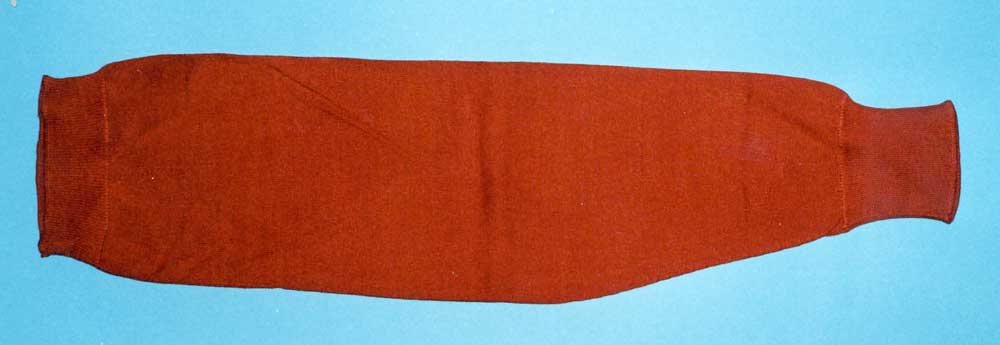

Undersleeve

Pair of ladies knitted undersleeves in dark red silk with ribbed cuff at top and bottom. 'E' knitted below cuff.

Vest

A close-fitting garment which extends to the waist or just below. The term generally refers to a type of underwear. Vests are usually collarless, and can be sleeveless or have short or long sleeves.

Waistcoat

Originally a man's close-fitting garment covering the upper body and extending to below the waistline. Waistcoats are buttoned at the front and are usually sleeveless. They are generally worn over a shirt and under a jacket. From the mid-nineteenth century, waistcoats were co-ordinated with matching jackets and trousers to form the three piece suit. Women began wearing waistcoats in the late nineteenth century.

Waistcoat

Man's waistcoat, the front hand-frame knitted in pale blue and white silk, the back of blue woven silk, lined with ivory and blue striped silk (both very fragile).Four front pockets, six brass buttons, five monogrammed 'JF', and four smaller buttons on back.

Wool

Wool has a long history of being used for clothes. Fragments of wool fibres have been recovered from sites in Egypt and Iraq dating to several thousand years B.C.

The Romans, as early as 200 B.C., began to improve the quality of wool produced by their flocks and created some of the ancestors of the sheep breeds we have in the world today.

Wool in common with hairs produced by other animals has a cylindrical shape and a scaly appearance when looked at under a microscope. The scales on the hair help the fibres to bind together when being spun. The fibre also has an elastic property that enables it to stretch to up to nearly twice its original length before breaking.

The fleece of a sheep is not the same across the sheep's body. The underside of the ewe's body for example, is a softer fleece than that found on the back. Variations in wool are an important consideration when processing fleeces to ensure that fibres of a particular style are matched up and used for the correct yarn type. For stockings, fine wool with a long length or 'staple' is required to produce a yarn suitable for use on a stocking frame. The sheep commonly found in the East Midlands area during the sixteenth century produced a long staple and helped to establish the industry there.

Once removed from the sheep, the fleece requires cleaning in a series of baths to remove trapped dirt. The cleaned wool is placed into a carding machine to remove trapped foreign matter such as seed heads and straighten out the fibres. The fibres are then combed to separate the long fibres from the short fibres. The long fibres are used to produce a consistent regular thread. A thread of fibres is then pulled or drawn from the wool to reduce it down to a thin 'roving' ready for spinning. Once spun, the yarn is ready for knitting.

Wool

Women's red/multi tartan wool glove. Long wrist banded in red and green, fingers and thumb in plain red moss stitch.

Wristlet

The term wristlet refers to a band of material worn around the wrist for decoration, warmth, or protection. Victorian knitted wristlets were frequently beaded.